On December 25, iMiracle (Shenzhen) Innovation Technology Co., Ltd. (hereinafter referred to as “Elfbar“) and Guangdong Fuli Intelligent Manufacturing Co., Ltd. (hereinafter referred to as “Ful Intelligent”) joined forces to demonstrate a new intelligent production line. Improve the manufacturing level of the electronic atomization industry and accelerate the innovative and high-quality development of the electronic atomization industry.

Fuli Intelligent is an innovative enterprise focusing on electronic atomization ODM and OEM. It can provide brand customers with one-stop service for the entire industry chain. It is the industry’s top integration of product definition, design and development, production and manufacturing, and supply chain management. solutions provider.

Founded in 2007, iMiracle is one of the earliest electronic atomization product export companies in China. In the first ten years since its establishment, it has gradually grown into the leading foreign trade company in the industry. From 2020 to 2022, AiMiracle successively launched well-known electronic atomization brands such as ELFBAR and LOST MARY, becoming one of the leaders in the globalization, branding and compliance of China’s electronic atomization industry.

Over the past 16 years, AiMiracle has built a team that is good at expanding overseas markets and insists on expanding overseas markets with its own brands. Working with Fuli Intelligent to upgrade the intelligent manufacturing industry chain is an important step for Miracle to bring China’s advanced experience in intelligent manufacturing abroad and empower Chinese brands to go global.

iMiracle and Fuli Intelligent have created a new intelligent production line, a fully digitalized intelligent cloud factory, and informalized the entire production process to support the new electronic atomization export business.

In the new intelligent manufacturing production workshop, the one-stop automation system has changed the original electronic atomization production process, forming automated processes ranging from automatic oil filling, automatic assembly of atomizers, and automated testing of finished products to automatic labeling and packaging of cigarette boxes, with high The efficient production features of integration, high yield and sterility have set a benchmark in the industry and created a safer, more compliant and more modern intelligent electronic atomization production line. In the Fuli smart factory, the number of ELFBAR and LOST MARY disposable and reloadable electronic atomization products produced every year reaches tens of millions.

At the same time, every ELFBAR and LOST MARY e-cigarette produced in the smart factory has undergone a series of high-standard tests, including toxicology testing, e-liquid and vapor chemical composition analysis, product reliability evaluation, material testing, electronic and battery safety test. FEWO has also established laboratories compliant with the European Union’s Restriction of Hazardous Substances Directive (RoHS) to assess the environmental impact of products.

In addition, the entire company is promoting digital transformation from top to bottom to create a smart cloud factory of “lean manufacturing and green production”. The intelligent cloud has greatly shortened the original product delivery cycle. Customers can place orders directly online and produce on demand. The flexible supply chain production line has completely changed the original production and manufacturing process, and the inventory cycle has also been shortened from the original 15 days to 5 days.

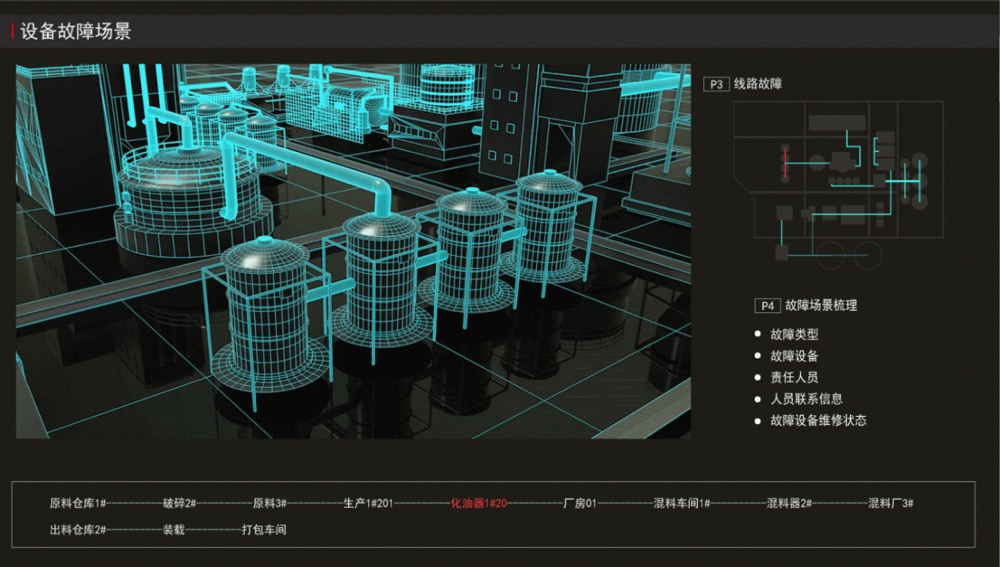

Intelligent manufacturing is also reflected in the construction of full-process informatization. Fuli Intelligent realizes the visualization of all equipment maintenance, maintenance and daily data. The safety and health of the equipment can be monitored online. Once an abnormality is discovered, the system can report an error in time and provide abnormal warning and feedback as soon as possible to reduce the cost of manual intervention.

It is understood that the electronic atomization industry needs continuous investment in materials, processes, basic research and other fields. Fuli Intelligence has more than 100 R&D personnel, holds more than 100 patents, and spends 5% of its revenue on innovative research every year. Currently, the company is building a Guangdong provincial engineering research center to support daily product quality inspection and reliability verification, while also conducting cross-border new material application research, global compliance product design, and upgrading the consumer experience in the electronic atomization industry.

Hu Enci, chairman of Fuli Intelligent, said: “In recent years, electronic atomization technology has been continuously iteratively upgraded. Facing the current status and future development of the industry, Fuli Intelligent has introduced intelligent production lines, actively accelerated the company’s digital transformation, and explored the integration of the entire process Informatization, carry out all-round brand upgrades from different dimensions, and strive to enter the era of electronic atomization industry 4.0 intelligent manufacturing.”

Fuli’s breakthrough in the field of intelligent manufacturing is in line with the regulatory requirements for building and consolidating the quality assurance system for electronic atomization products. It adheres to the principles of safety first, prevention first, risk management and control, and full-process control. By actively digesting the world’s advanced technologies, Rules and standards have focused on improving product quality, ensuring the safety of electronic atomization products, and helping to improve the quality level of products in the entire industry.

With the innovation and iteration of atomization technology, the electronic atomization industry also continues to make breakthroughs in new technologies, new materials, new business formats, etc., becoming one of the business cards of “Intelligent Manufacturing in China”. In the future, AiMiracle will join forces with Fuli Intelligent to build a more modern and smarter production line, continue to establish an industrial pattern of “intelligent manufacturing in China, global consumption”, and accelerate the high-quality development of the electronic atomization industry.